eMesh concrete steel mesh replacement

100% RECYCLED MACRO SYNTHETIC FIBRE CONCRETE MESH

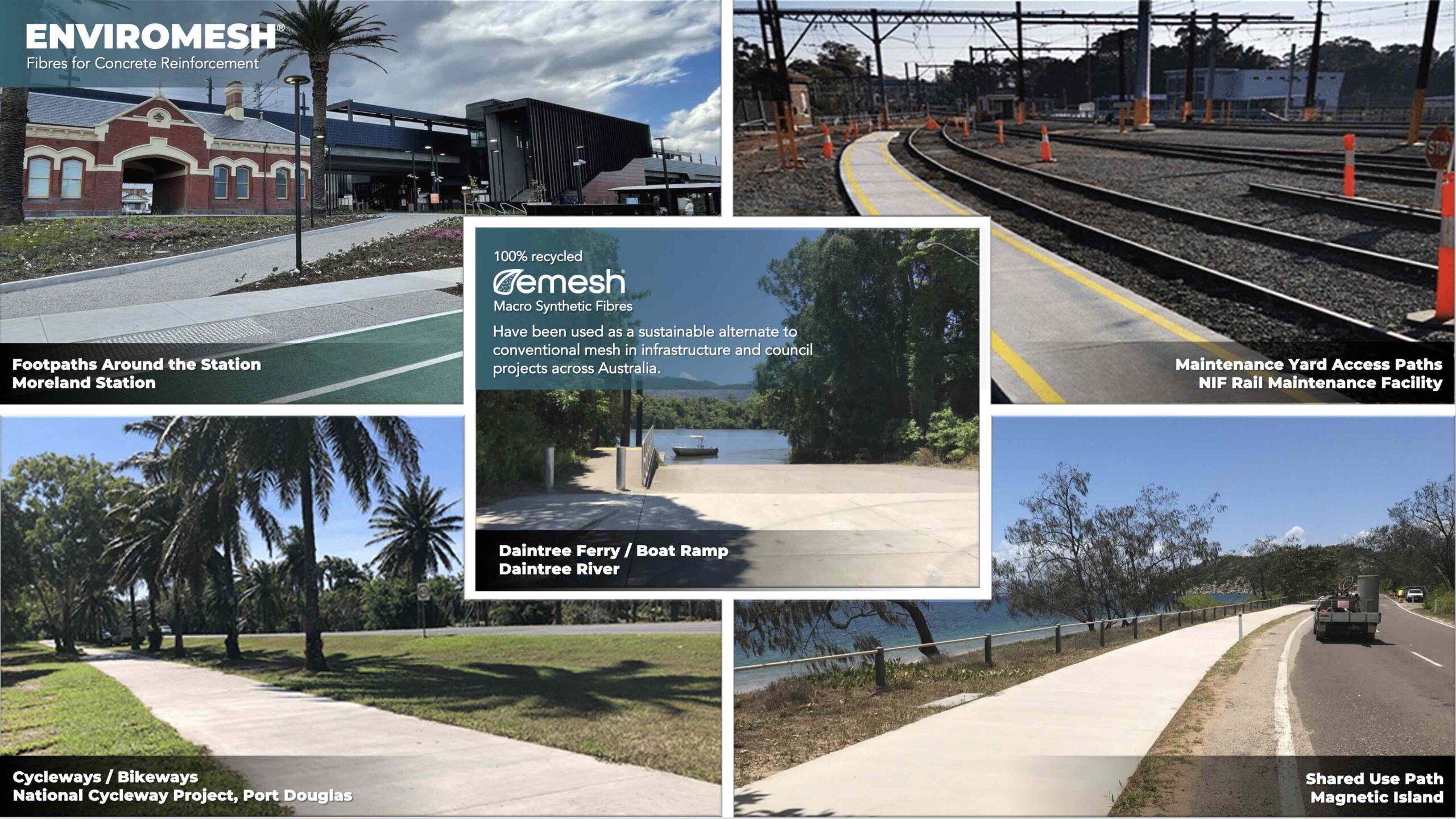

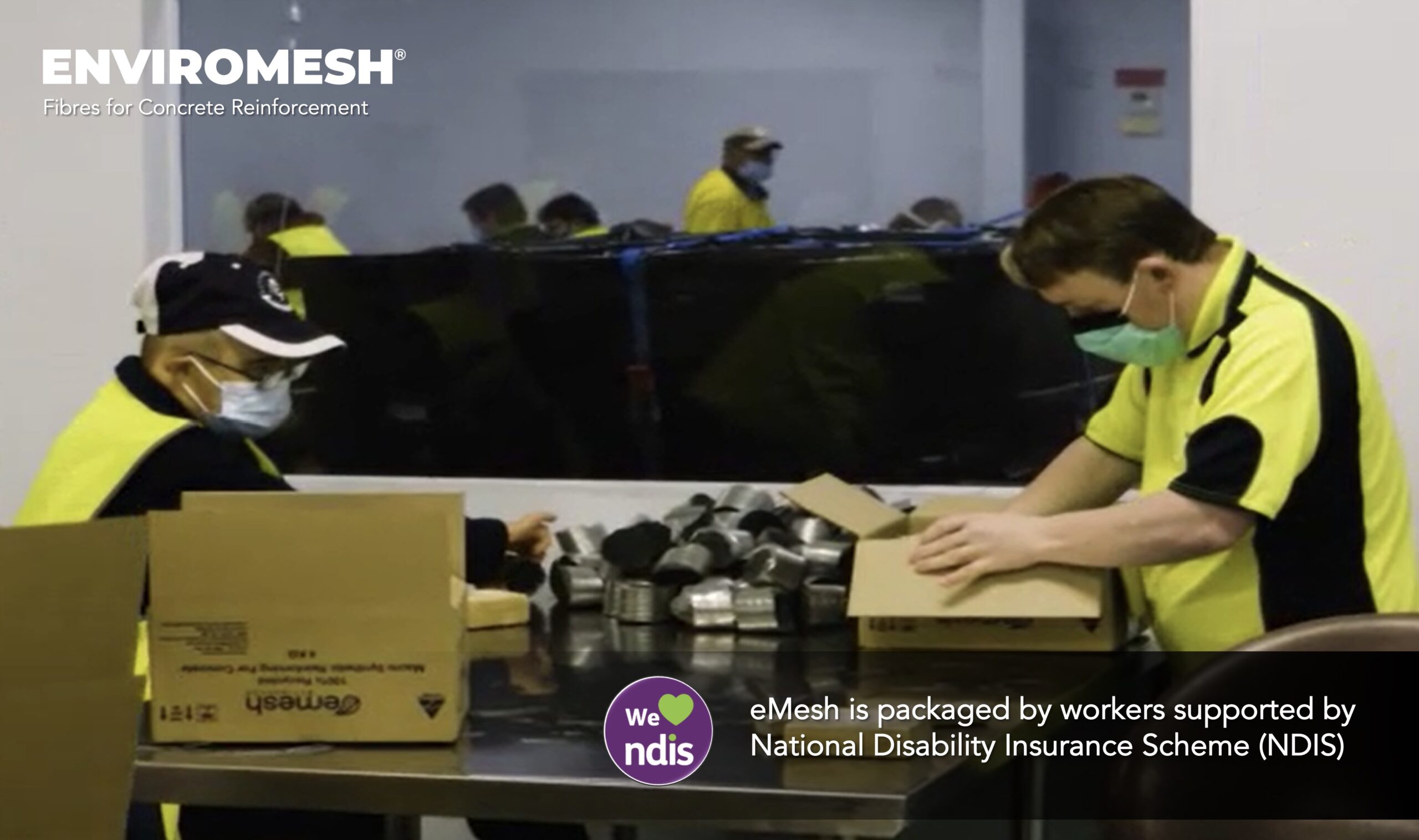

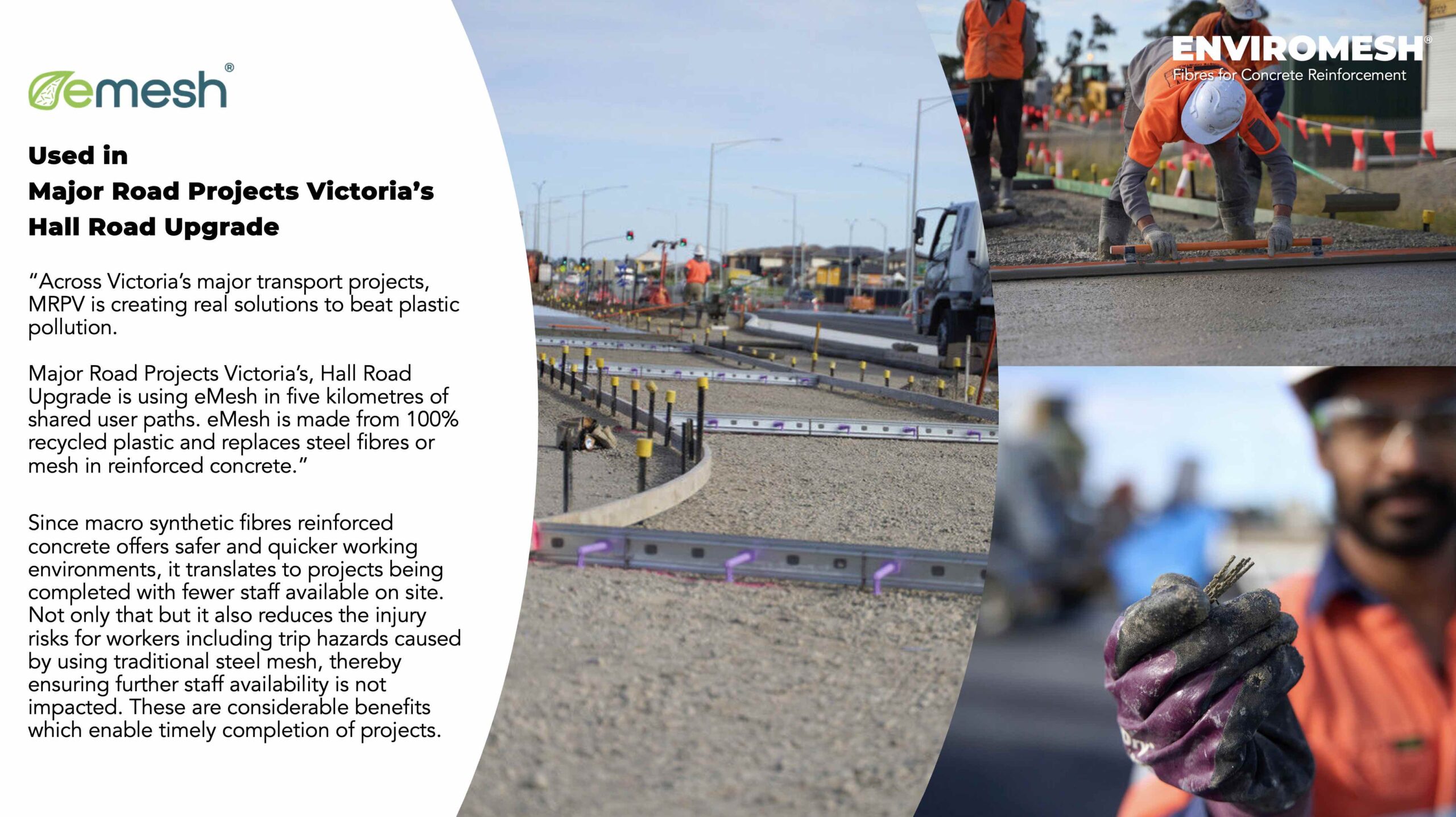

eMesh 100% recycled macro synthetic fibre by Enviromesh, made in Australia, and packaged by National Disability Insurance Scheme (NDIS) workers, was proposed to replace steel mesh reinforcement in the concrete shared user paths (SUPs) and footpaths by North Western Program Alliance (NWPA) for the Bell to Moreland Level Crossing Removal Project (B2M LXRP). Reductions in CO2 and PO4 emissions were more than 90% achieved, water and fossil fuel consumption were more than 90% reduced and 200 hours of NDIS employment were created by replacing steel mesh with eMesh, encouraging a deeper examination of other associated benefits, indirect savings and efficiencies of eMesh by NWPA. Areas examined included site activities and compliance, which outlined reduced safety risks on site to workers, time lost due to coordinating, moving and unloading steel mesh deliveries, and reduced pre-pour engineering inspection requirements for eMesh reinforced concrete (no steel mesh to inspect).

The savings across these many areas, which are complemented by site efficiencies and time reduction in construction, provided a clear positive outcome for the decision to adopt the use of eMesh by Major Road Projects Victoria (MRPV) and Rail Projects Victoria (RPV) for future works, with potential for greater improvements across many of the Big Build projects. The potential emission reductions and reuse of waste plastic across future projects, since successful implementation at B2M, is extensive and will provide long term repurposing of a waste stream.

The process to have eMesh approved for use on the B2M project began in late 2019 and early 2020, where, after consultation, design checks, environmental assessment and inspection of existing SUPs at Skeleton Creek (Hobsons Bay, constructed in 2017), a decision was made by NWPA to present a proposal to Metro Trains Melbourne and the Level Crossing Removal Authority for use of eMesh. The proposal was accepted and eMesh was implemented into the project.

Throughout the approval process, which took more than 6 months, and then implementation, there were clear learnings that to introduce a product that is non-standard, the assessment process needs to be clear and concise, backed by evidence and published research. The practical implementation also requires engagement with all levels down to the subcontractor on site. Clear knowledge sharing around how to use, design with and environmentally assess the new product is a key part of success, and B2M showed us this needs to be a strong focus.

For future projects, the engagement of all parties, from concrete suppliers to contractors placing the concrete, is paramount to continued improvement and achieving quality outcomes. Lessons learned are already being implemented across many LXRP, MRPV and RPV projects and will continue to be shared to create continued improvements and quality outcomes.