Case Study -HYDI hydrogen-on-demand trial – reducing diesel use at METRONET’s Byford Rail Extension

Background

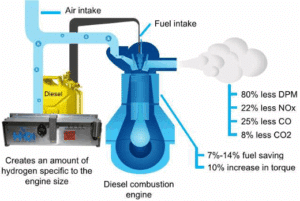

As part of the METRONET Byford Rail Extension project in Western Australia, two ISC members collaborated to find sustainable solutions that support the transition to a net zero economy. The MetCONNX Alliance (Public Transport Authority, Laing O’Rourke, Pritchard Francis Consulting and KBR) trialled a hydrogen-on-demand technology developed by HYDI, specialists in hydrogen solutions for internal combustion engines. HYDI's compact, self-contained unit generates hydrogen from demineralised water using proton exchange membrane (PEM) cells that are injected into diesel engines to improve combustion efficiency and reduce emissions.

Unlike purpose-built hydrogen vehicles, HYDI units can be retrofitted to existing diesel-powered equipment, making them a practical and scalable solution for hard-to-abate sectors such as construction. The trial aligns with METRONET’s sustainability strategy pillars of environment, economy, and governance, and supports the broader industry transition to net zero.

Implementation and results

A HYDI unit was installed on a Plantech CAT 962 loader operating on the Byford Rail Extension. Fuel consumption data was collected before and after installation:

- Pre-HYDI: 8.18 litres/hour

- Post-HYDI: 6.56 litres/hour

- Hours operated: 130

- Diesel saved: approximately 210.6 litres

- Water used: 3.5 litres of distilled mineral water

- Estimated fuel efficiency improvement: approximately 19%

Operator feedback confirmed noticeable improvements in fuel efficiency. The loader has since been off-hired, and the HYDI unit will be installed on another machine to continue monitoring performance.

Impact delivered

The trial demonstrated measurable environmental, health, and financial benefits:

- Environmental: Estimated diesel efficiency gains of 10–20%, with proportional reductions in CO₂e emissions

- Health and safety: Reduced exposure to diesel fumes, which are linked to asthma, headaches, and lung irritation, noting that the open-air construction site naturally dissipates fumes normally.

- Financial: Return on investment under two years, with a unit lifespan of approximately 20 years. The trial enhances the reputational image of MetCONNX, PTA, and METRONET as leaders in sustainable innovation

Lessons learned

- HYDI units are most effective when installed on equipment with longer site durations due to installation costs

- Early data suggests strong potential for broader industry adoption, particularly in sectors where electrification is not yet scalable

- Monthly tracking of fuel efficiency will continue, with findings to be shared with industry to support market transformation

Looking ahead

MetCONNX believes this is a construction and Western Australian first. The team is working to verify this and explore further applications. Toolbox talks and knowledge-sharing sessions are underway to educate the workforce and supply chain, and the ISC is working to raise awareness of this technology across its network.