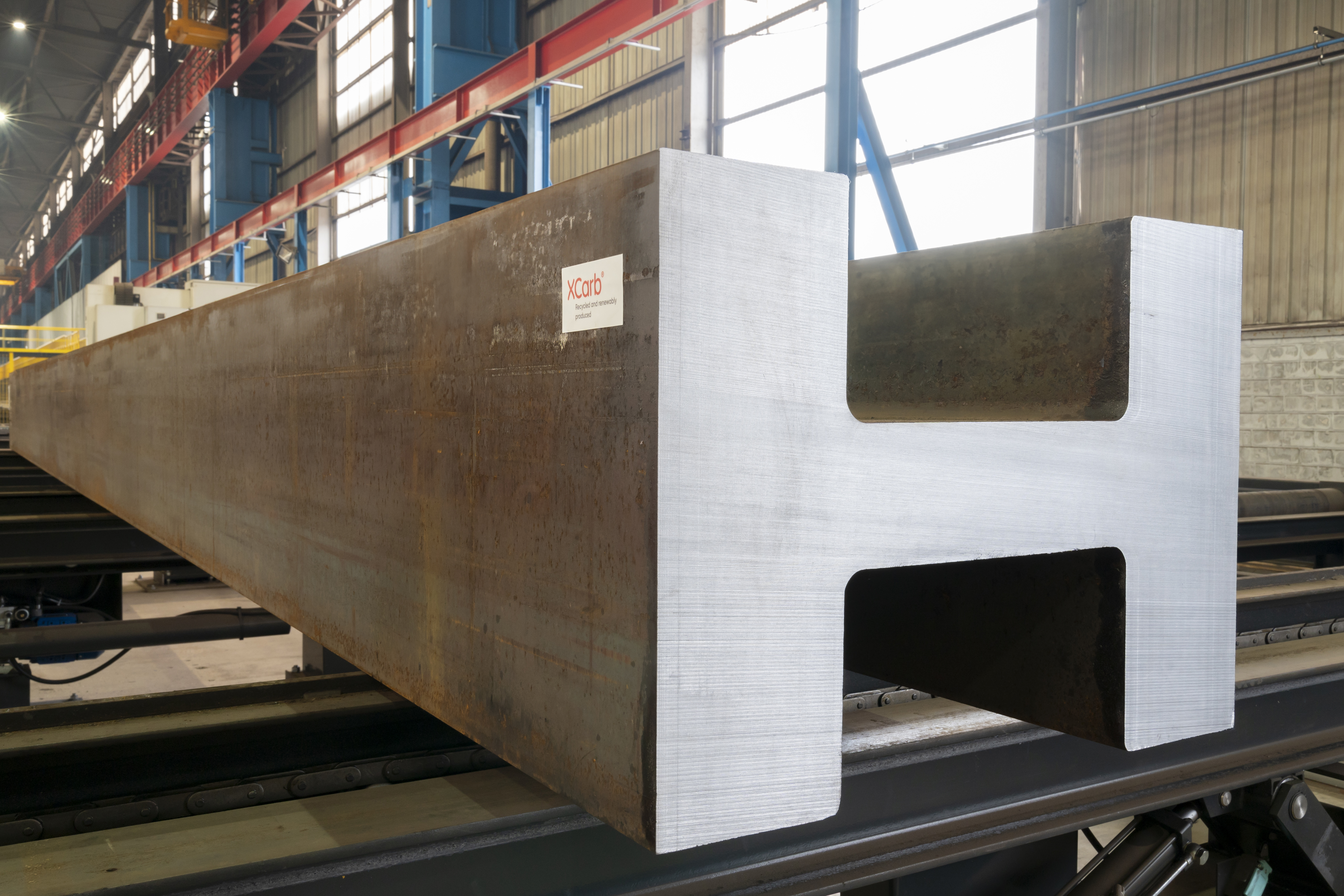

XCarb® recycled and renewably produced

Details

- Product Type Metals

- Regions Australian Capital Territory, New South Wales, Northern Territory, Queensland, South Australia, Tasmania, Victoria, Western Australia

Contact

- J Steel 0281989500

- Website Visit

- Email sales@jsteel.com.au

ISupplier

- Company Name J Steel Australasia Pty Ltd

- ISupplier Profile Visit

About

XCarb® recycled and renewably produced refers to products made via the Electric Arc Furnace route using up to 100% scrap and 100% renewable energy. The renewable electricity comes from recent projects of solar and wind power, which are connected to the same grid as the production sites. The electricity used in the steelmaking process is independently verified, with a ‘Guarantee of Origin’ given that it is from renewable sources. Environmental Product Declarations (EPD) for XCarb® are independently verified and comply with ISO 14025 and EN15804 standards. Our listing is for XCarb® hot rolled structural sections. The other products available in XCarb® include: – floor decking – design facades and wall sidings – steel sheets, mesh, strands, grating, fencing

Sustainability Outcomes

XCarb® recycled and renewably produced products have an extremely low CO₂ footprint that can be as low as approximately 0.33 tonnes CO2 per tonne of finished steel when the metallics are 100% scrap. This is a significant reduction compared to the local industry average of 2.85 tonnes. The extremely low CO₂ footprint is owed to the end-of-life scrap steel used in the steel making process for XCarb®. This integrates into the circular economy concept as steel can be infinitely recycled with no loss of quality. The CO2 footprint is further reduced through the Electric Arc Furnace route and by using 100% renewable energy from solar and wind power. The sustainability benefits of XCarb® include: – Conserving natural resources and reducing carbon emissions associated with the mining and extraction of raw materials – Use of electric arc furnace, powered using 100% renewable energy significantly lowers the carbon emissions and environmental impact when compared to traditional blast furnace – Recycling end-of-life steel material and reducing the quantity diverted to waste and associated waste management activities – Supports a circular economy and promotes use of steel, which can be disassembled for reuse and readily recovered/recycled

Applicable Credits

| IS v2.1 | Ene-3 , Inn-1 , Rso-1 , Rso-4 , Rso-5 , Rso-6 , Rso-7 |

| IS v1.2 | Inn-1 , Mat-1 , Mat-2 , Was-2 , Was-3 |

| Mat-1 (ISv1.2) | The use of XCarb® can significantly reduce embodied carbon (Scope 3 Indirect Emissions) for hot rolled steel sections used on a project. The carbon footprint of XCarb® is 0.33 tonnes CO₂ per tonne of steel, a significant reduction compared to the local industry average of 2.85 tonnes per tonne of steel. By prescribing XCarb® steels in design, projects can significantly reduce upstream Scope 3 Emissions and reduce end-of-life impact through reuse and recycle. Carbon emissions can be further reduced through the use of large dimension hot rolled steel sections up to 600mm height for columns and 1100mm height for beams. These sections can replace complex, welded built up sections which incur additional carbon emissions from manufacturing, processing and transport. Optimising design and material efficiency using high strength, large dimension, hot rolled XCarb® steels has potential to achieve reduction in weight and size of steel members required, thus reducing the carbon footprint of production, transport and eventually recycle or repurposing of steel materials. |

| Mat-2 (ISv1.2) | The producer of XCarb®, ArcelorMittal has a strong commitment to their ongoing global programme of steelmaking innovation targeted at carbonneutral steel by 2050. ArcelorMittal is a founding member of ResponsibleSteelImage removed by sender. ™, Picture and has been recognised by World Steel Asocation, Carbon Disclosure Project for corporate transparency and action on climate change. One of ArcelorMittal\'s decarbonisation intiatives is the XCarb® recycled and renewably produced label. This label refers to steels produced in an electric arc furnace (EAF) using high levels of scrap and 100% renewable electricity. The focus of XCarb® is to work towards carbon neutral steel. EPDs can be used to quantify all environmental impacts and Guarantee of Origin can be used to verify supply of renewable electricity used for the production of XCarb® steel. |

| Was-2 (ISv1.2) | The use of steel helps divert materials from landfill. Steel is a durable and versatile material that can be used for temporary and permanent applications. It is 100% recyclable and can be infinitely recycled without loss of quality. Being magnetic, steel can be easily recovered. Steel structures can also be disassembled and repurposed. This significantly reduces raw material extraction and energy required for producing new steel. |

| Was-3 (ISv1.2) | Steel members are highly adaptable and reusable due to their durability and strength. Being a modular component, steel can be readily disassembled and repurposed for different environments and applications. When designed for disassemble and reuse, steel products can be reused with minimal reworking. This significantly reduces raw material extraction and energy required for producing new steel. |

| Inn-1 (ISv1.2) | The use of XCarb® contributes to Innovation Challenge-8: Sustainable Suppliers and ISupply |

| Inn-1 (Isv2.1) | The use of XCarb® contributes to Innovation Challenge-4: Sustainable Suppliers and ISupply |

| Ene-3 (ISv2.1) | XCarb® green steel certificates documents savings in carbon emissions in the form of a certificate. Projects can purchase green steel certificates and demonstrate reduction in Scope 3 emissions (A1 - A3 Embodied Carbon) and offset embodied carbon for the Project. Green steel certificates are verified by an independent auditor in accordance with the GHG Protocol Corporate Accounting and Reporting Standard. The green steel certificates (a carbon emissions off-setting scheme under ArcelorMittal’s XCarb® initiative) does not apply for the products listed in this application (hot-rolled structural steel sections) noting that these are benefitting from a direct carbon emissions reduction by means of steel produced through a 100% steel scrap – EAF route using (100%) renewable energy, in particular, wind and solar. |

| Rso-1 (ISv2.1) | The use of steel and in particular the innovative XCarb® steel contributes to a circular economy and enhances material efficiency over the material and project life cycle. This includes: - Significantly reducing upstream Scope 3 emissions from the raw materials and manufacturing stage - Potential to reduce weight/volume of steel by optimising material efficiency - Durability minimises the need for repair or replacement - At end of life, steel members can be readily recycled and repurposed |

| Rso-4 (ISv2.1) | The use of steel helps divert materials from landfill. Steel is a durable and versatile material that can be used for temporary and permanent applications. It is 100% recyclable and can be infinitely recycled without loss of quality. Being magnetic, steel can be easily recovered. Steel structures can also be disassembled and repurposed. This significantly reduces raw material extraction and energy required for producing new steel. |

| Rso-5 (ISv2.1) | Steel members are highly adaptable and reusable due to their durability and strength. Being a modular component, steel can be readily disassembled and repurposed for different environments and applications. When designed for disassemble and reuse, steel products can be reused with minimal reworking. This significantly reduces raw material extraction and energy required for producing new steel. |

| Rso-6 (ISv2.1) | The use of XCarb® can significantly reduce embodied carbon (Scope 3 Indirect Emissions) for hot rolled steel sections used on a project. The carbon footprint of XCarb® is 0.33 tonnes CO₂ per tonne of steel, a significant reduction compared to the local industry average of 2.85 tonnes per tonne of steel By prescribing XCarb® steels in design, projects can significantly reduce upstream Scope 3 Emissions and reduce end-of-life impact through reuse and recycle. Carbon emissions can be further reduced through the use of large dimension hot rolled steel sections up to 600mm height for columns and 1100mm height for beams. These sections can replace complex, welded built up sections which incur additional carbon emissions from manufacturing, processing and transport. Optimising design and material efficiency using high strength, large dimension, hot rolled XCarb® steels has potential to achieve reduction in weight and size of steel members required, thus reducing the carbon footprint of production, transport and eventually recycle or repurposing of steel materials. |

| Rso-7 (ISv2.1) | The producer of XCarb®, ArcelorMittal has a strong commitment to their ongoing global programme of steelmaking innovation targeted at carbonneutral steel by 2050. ArcelorMittal is a founding member of ResponsibleSteelImage removed by sender. ™, Picture and has been recognised by World Steel Asocation, Carbon Disclosure Project for corporate transparency and action on climate change. One of ArcelorMittal\'s decarbonisation intiatives is the XCarb® recycled and renewably produced label. This label refers to steels produced in an electric arc furnace (EAF) using high levels of scrap and 100% renewable electricity. The focus of XCarb® is to work towards carbon neutral steel. EPDs can be used to quantify all environmental impacts and Guarantee of Origin can be used to verify supply of renewable electricity used for the production of XCarb® steel. |