COLORBOND® Coolmax® steel

Details

- Product Type Life Cycle Assessment & EPD Development, Products

- Regions Australian Capital Territory, New South Wales, Northern Territory, Queensland, South Australia, Tasmania, Victoria, Western Australia

Contact

ISupplier

- Company Name BlueScope

- ISupplier Profile Visit

About

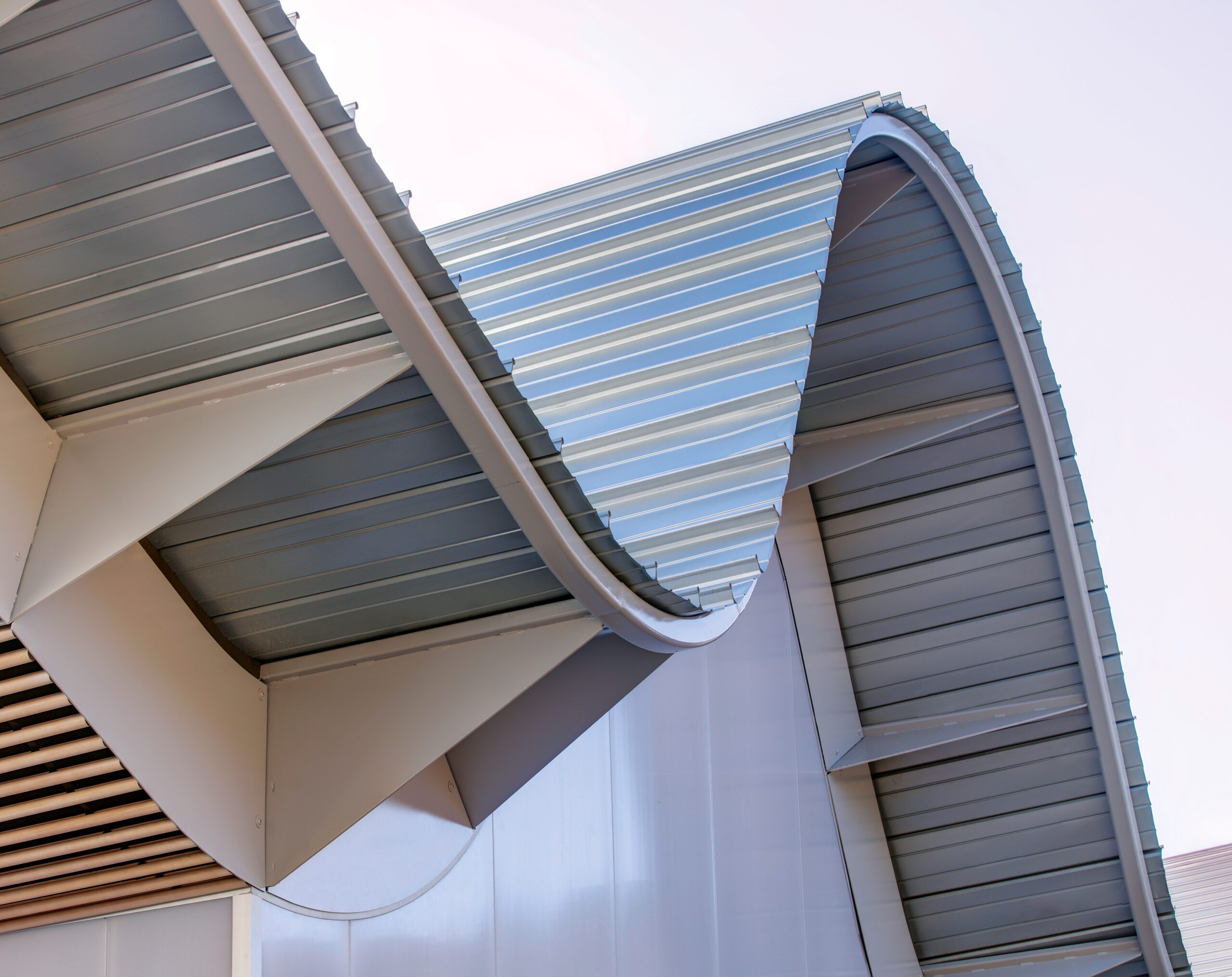

COLORBOND® Coolmax® steel (CMX) is BlueScope’s roofing material designed to provide and

maintain high solar reflectance. COLORBOND® Coolmax® steel, available exclusively in the colour

Whitehaven®, is specifically designed to provide low solar absorptance to help reduce roofing

temperatures. Typical COLORBOND® Coolmax® steel applications are for commercial and industrial

roofing.

COLORBOND® Coolmax® steel consists of a steel substrate that is coated with a metallic coating

incorporating BlueScope’s Activate® technology (hot dipped aluminium, zinc, and magnesium alloy

AM100 coating) to provide enhanced corrosion resistance, and then further protected and enhanced

with a specially developed, exterior-grade, oven-baked paint system designed specifically for high

solar reflectance.

COLORBOND® Coolmax® steel is strong, durable, thermally efficient, meets all relevant Australian

Standards (AS 1397:2021 and AS/NZS 2728:2013).

Sustainability Outcomes

BlueScope embraces circular economy principles in product development, including designing

products for durability and resilience.

Steel is strong, durable, and versatile and its inherent properties allow it to be recycled without loss

of quality over and over again. In some cases, it can be reused without reprocessing, again saving on

energy and resource use.

The steel in COLORBOND® Coolmax® steel is 100% recyclable and its magnetic properties mean that

it can be easily separated for recycling and is less likely to end up in landfill.

BlueScope’s Port Kembla Steelworks site, where the steel for COLORBOND® Coolmax® steel is

manufactured, is certified to the ResponsibleSteel™ Standard v1.1.

The ResponsibleSteel™ certification can give organisations in the steel value chain confidence in the

environmental, social and governance performance of our steelmaking facilities, and may help them

to meet their climate objectives and manage supply chain risks.

Applicable Credits

| IS v1.2 | Inn-1 , Mat-1 , Mat-2 , Was-2 , Was-3 |

| IS v2.1 | Inn-1 , Rso-4 , Rso-5 , Rso-6 , Rso-7 |

| Mat-1 | Materials life cycle impact measurement and reduction | The use of BlueScope's steel products with Environmental Product Declarations (EPDs) can help to demonstrate the environmental impacts of the project vs a reference building or structure - the COLORBOND® Coolmax® steel EPD can be used to represent the impact of the product in whole-of-building or structure Life Cycle Assessment (LCA) and in the IS Materials Calculator. |

| Mat-2 | Environmentally labelled products and supply chains | COLORBOND® Coolmax® steel may meet environmental labelling requirements of the IS Rating through its GreenRate™ ‘Level A’ certification and product-specific EPD. |

| Was-2 | Diversion from landfill | The magnetic properties of steel mean that it can be easily separated for recycling and the inherent value of steel scrap results in a high recovery rate. In Australia, this is evidenced by a recycling rate for metals of 90% (National Waste Report, 2020). The steel in COLORBOND® Coolmax® steel is 100% recyclable without loss of quality. In some cases, it can be reused without reprocessing, again saving on energy and resource use. |

| Was-3 | Deconstruction/Disassembly/Adaptability | Steel is a strong, durable, and versatile material. BlueScope's steel products lend themselves well to structures that are designed for long life, resilience, and flexibility to accommodate multiple future reuse options without reinvestment in structural alteration and refurbishment. Steel also supports designs where end of life considerations are key, e.g. designing for disassembly and reuse. |

| Inn-1 (ISv1.2) | Contributes to Innovation Challenge-8: Sustainable Supplier and iSupply | |

| Rso-4 | Resource Recovery and Management | The magnetic properties of steel mean that it can be easily separated for recycling and the inherent value of steel scrap results in a high recovery rate. In Australia, this is evidenced by a recycling rate for metals of 90% (National Waste Report, 2020). The steel in COLORBOND® Coolmax® steel is 100% recyclable without loss of quality. In some cases, it can be reused without reprocessing, again saving on energy and resource use. |

| Rso-5 | Adaptability | Steel is a strong, durable and versatile material. BlueScope's steel products lend themselves well to structures designed for long life, resilience, and flexibility to accommodate multiple future reuse options without reinvestment in structural alteration and refurbishment. Steel also supports designs where end of life considerations are key, e.g. designing for disassembly and reuse. |

| Rso-6 | Materials life cycle impact measurement and reduction | The use of BlueScope's steel products with Environmental Product Declarations (EPDs) can help to demonstrate the environmental impacts of the project vs a reference building or structure - the COLORBOND® Coolmax® steel EPD can be used to represent the impact of the product in whole-of-building or structure Life Cycle Assessment (LCA) and in the IS Materials Calculator. |

| Rso-7 | Sustainability labelled products and supply chains | COLORBOND® Coolmax® steel may meet environmental labelling requirements of the IS Rating through its Product-specific EPD. |

| Inn-1 (ISv2.1) | Contributes to Innovation Challenge-4: Sustainable Supplier and iSupply |