Project Description

The Bexley North and Petersham station upgrade projects included a range of works to improve accessibility, security and amenity for public transport users. The two stations were upgraded as part of the TfNSW TAP3 program which aims to provide universal access and compliance with disability legislation. The scope of works included utilities works and service relocations, new station entrances, footpath upgrades, demolition works, new lifts, new stairs, canopy and platform upgrades, new toilets, communications room upgrades, car park upgrades, stormwater/drainage works, tree removals, landscaping and other ancillary works.

The project prioritised sustainability throughout design, and focussed on reducing the projects greenhouse gas emissions, reduce materials use, maximise energy and water efficiency, reduce pollution and waste and to enhance positive social and economic outcomes for the community. The project went beyond small project pathway requirements, pursued several innovations and was awarded a leading rating for design with a score of 90.59

The information below details how these aspects were achieved.

Key Achievements

- Project collaboration, management and governance – setting up the project for success involved gaining the commitment and involvement of the project’s senior management in the sustainability deliverables and a project-wide team alignment to those deliverables. In addition to being a project-wide effort, the project also allocated dedicated resources to delivering the ISC rating and ensuring sustainability was both integrated into the project system and that there were clearly allocated responsibilities for sustainability outcomes. These efforts were underpinned by Arenco’s Environmental and Sustainability policy and ongoing support by Senior Management. The project also made commitments to specific outcomes related to its ISC rating, in relation to procurement, energy, water, climate change, materials, discharges, health, waste, heritage and stakeholder engagement. The project teams committed to achieving certain innovations in materials and emissions, and exceeded the small project pathway requirements on a number of occasions.

- Carbon neutral concrete – All readymix concrete supplied to the project by Holcim was carbon neutral, through a combination of offsets and high Supplementary Cementitious Materials (SCMs), with further reductions achieved through value engineering and design measures carried out by Arenco. At the time of concrete pouring this was the 2nd project in Australia to adopt this initiative, and was first in a metropolitan area (see highlight 1 below).

- Waste-to-energy initiative – the projects waste subcontractor (Grasshopper) sent over 110 tonnes of waste to be repurposed as Processed Engineered Fuel (PEF) in a Waste-to-energy facility (see highlight 2 below).

- Waterless vac trucks – these were used as a construction water and liquid waste saving initiative, avoiding the use of over 2800l of water (see highlight 3 below).

- Design score of 90.59 – This project achieved a design score of 90.59

Some key learnings came out of the project in relation to maximising sustainability outcomes, including:

- Start early, implement systems, and raise awareness.

- Ensure whole team involvement & proper management of sustainability deliverables.

- Always pursue sustainability innovations even if they are hard or unorthodox.

- Demonstrate value for money and potential cost savings of sustainability deliverables.

- Give credit and recognition to innovators, whether they be on the project or outside.

- Provide clear and instructive subcontracts to suppliers on sustainability expectations.

- Be rigorous around collecting data and reporting on sustainability progress.

Highlights

Highlight 1: Carbon neutral concrete

All readymix concrete supplied by Holcim at both Petersham and Bexley North is carbon neutral, meaning a significant portion of the project’s overall material footprint is net zero. This is through a combination of offsets and high SCM, with further reductions achieved through value engineering measures. The project has been awarded innovation points as an Australian First (alongside Dubbo Regional Rail).

In addition, at Petersham station, the number concrete piles have been reduced from 10 to 6, reducing the number and depth of concrete piles in the cantilevered ramp structure from the carpark at Trafalgar St (reducing the use of concrete and reinforcement steel). In Bexley North station, the carpark pavement design was also minimised, reducing the use of asphalt and subbase. In addition, at least 20% recycled asphalt pavement will be adopted at Bexley north for the car park extension. Further, all major materials by spend (namely steel and concrete) are covered by Environmental Product Declarations.

Highlight 2: Waste-to-energy initiative

Whole-of-life thinking and circular economy principles have been applied to waste on the project, which the preferred waste contractor (Grasshopper) helped to drive by implementing waste-to-energy initiatives for Bexley North and Petersham.

Waste-to-energy is an ideal solution for non- recyclable plastics, cardboard, paper, textiles, and waste timber that would traditionally end up in landfill. The ground-breaking solution of converting waste to energy provides multiple benefits to the environment as it reduces greenhouse gas emissions, diverts waste away from landfill, enhances the circular economy and forms part of a greater solution to fossil fuels. To date, over 110t of diverted waste has been used as waste to energy, mostly as processed engineered fuels.

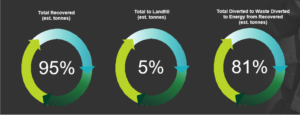

Petersham

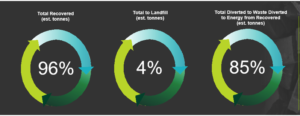

Bexley North

Highlight 3: Waterless vac trucks for construction water saving initiative

Waterless vac trucks are relatively new and significantly underutilised in the industry and to date have only been used on a handful of projects in NSW. The significant advantage of these dry vacs (compared to a traditional wet vacuum truck) is that they eliminate the use of high-pressure water, which avoids the generation of significant amounts of liquid waste, reduces the number of trips back and forward to the waste facility, and leads to considerably cheaper waste disposal (as the material is dry). This initiative saved over 2,800L of water for this project, as well as considerable waste disposal savings.

Petersham Station

Bexley North Station

Lift and lights at Petersham Station

Acknowledgements

- Arenco (Main Contractor) for taking ownership of the process and enabling the resources for the team to pursue a leading rating.

- Smart Infrastructure Consulting (Sustainability consultants)

- DesignInc – Urban Design and Architecture

- GHD – Design/Engineering consultants and sustainability design support

- TfNSW – Client

- Holcim – Carbon Neutral Concrete

- Grasshopper – waste contractor and responsible for waste-to-energy initiatives

Australian Firsts

- All readymix concrete on Bexley Nth & Petersham is net zero. This is the first project in a metropolitan area in Australia to adopt this initiative and along has been awarded Australian first (along with Dubbo Regional Rail).