Hatelit C40/17 eco Asphalt Reinforcement Grid

Details

- Product Type Asphalt and Bitumen, Construction Services, Engineering Services, Geosynthetic Materials

Contact

- Charmaine Cheah 07 3088 8000

- Website Visit

- Email charmaine@huesker.com.au

ISupplier

- Company Name HUESKER Australia

- ISupplier Profile Visit

About

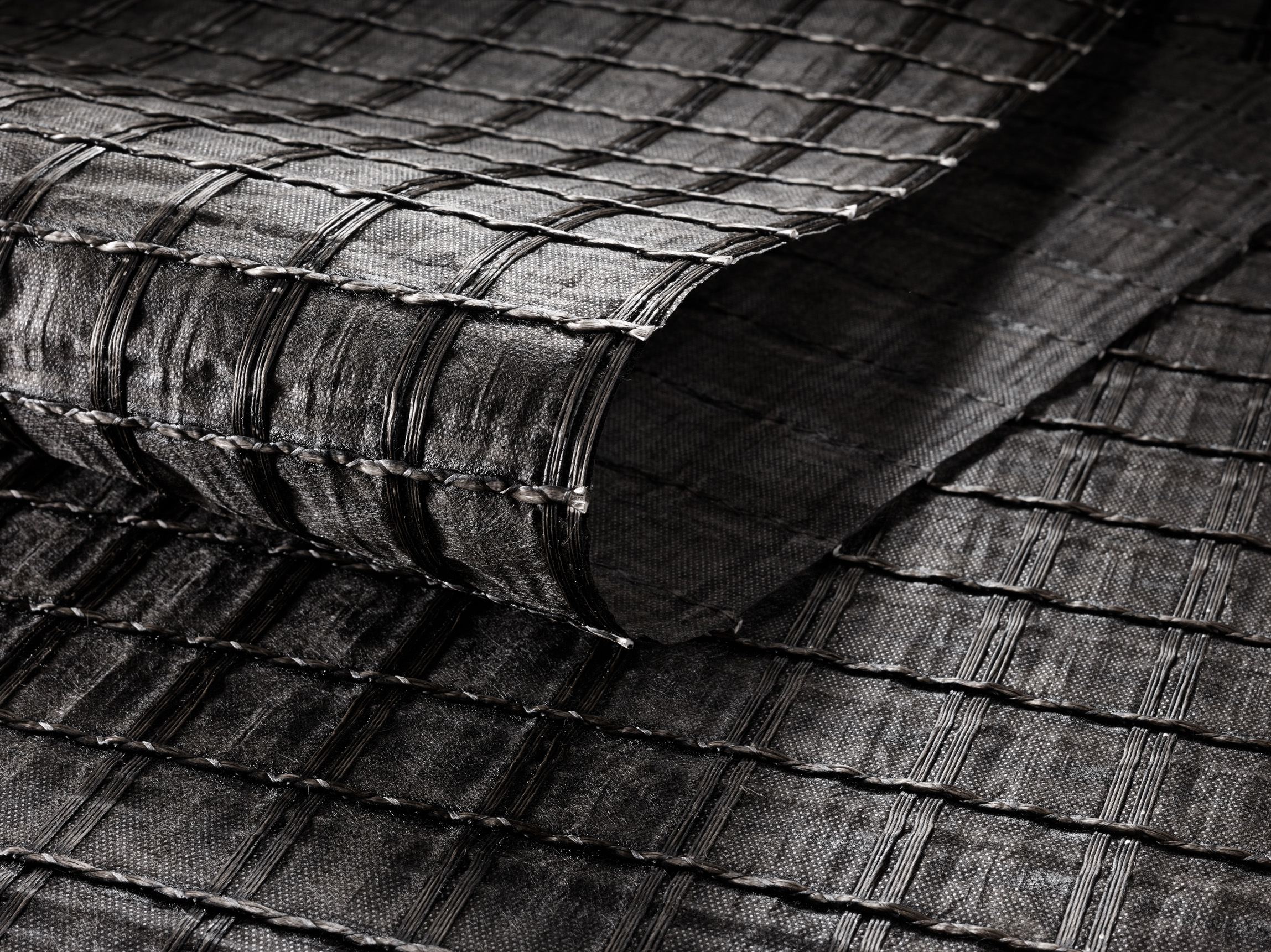

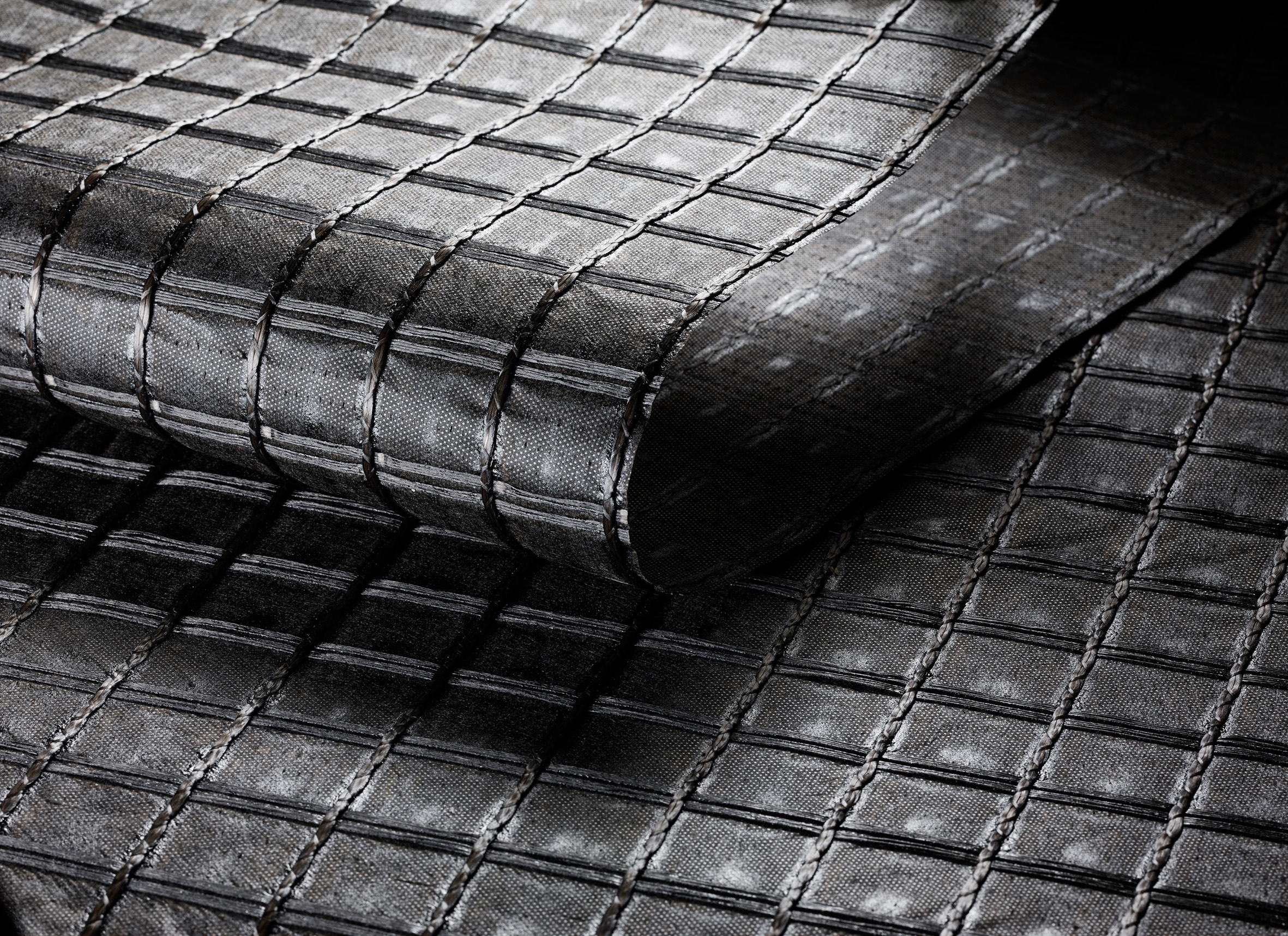

HaTelit has been successfully applied into asphalt reinforcement applications since 1971. The HaTelit C 40/17 eco reinforcement grid consists of high modulus polyester yarns made from 100% recycled PET bottles in combination with an ultra-lightweight non-woven fabric. The sustainable ecoLine product variant has been proven to have the same properties as the classic HaTelit C 40/17 product made from original fibres. Thanks to the state-of-the-art production process, the PET recycled yarn also achieves original fibre quality. With this product variant, we offer you a sustainable solution for the reinforcement of asphalt layers with the highest geotextile quality.

Sustainability Outcomes

The incorporation of HaTelit C 40/17 eco into a pavement rehabilitation design not only extends the service life of the asphalt layers above it, it has the potential to eliminate 24,900kg of CO2 emissions into the environment for every kilometre of road it is applied in. t provides sustainable, economic and financial outcomes in all phases of the project by reducing maintenance costs, increasing asset longevity and reducing carbon emissions and possible emission penalties. Although asphalt reinforcement is not a new technology, this initiative is fairly new in Australia and may be considered innovative. The incorporation of asphalt reinforcement in various level of road layer works provides various sustainable advantages over what is considered traditional pavement construction.

HaTelit C40/17 eco allows for the reuse of aggregates recycled on site. It can also be recycled and reused in road and runway pavements.

Studies confirm significant CO2 reduction through geosynthetics. Geosynthetics are high-quality and durable synthetic materials whose sustainability is proven.

The 2010 study “Sustainable Geosystems in Civil Engineering Applications” (WRAP) impressively demonstrates the significant savings potential in the use of geosynthetics on the basis of individual case studies. Compared to conventional construction methods, up to 89% CO2 emissions may be saved.

Innovative geotextiles can thus make a resource-efficient contribution to permanently reducing CO2 emissions in the construction industry.

Further to this the significant CO2 emission reduction further benefits are:

– Longer maintenance intervals means less construction sites and traffic jams

– Faster rehabilitation compared to conventional methods

– Best delay of reflection cracking

– Highest resistance to paving damage

– Particularly resistant to permanent dynamic traffic loads

– No loss of strength due to moisture

– Due to the flexibility and mechanical properties of the polyester, it is suitable for use on milled surfaces.

EPD – This product now has an EPD for greater data transparency, please contact manufacturer for details.

Applicable Credits

| IS v1.2 | Ene-1 , Inn-1 , Mat-1 , Mat-2 , Pro-2 , Urb-1 , Was-2 , Was-3 |