Basal Geogrids and Geocomposites

Details

- Product Type Geosynthetic Materials

- Regions Auckland, Australian Capital Territory, Christchurch, Dunedin, Hamilton, Lower Hutt, Napier & Hastings, Nelson, New Plymouth, New South Wales, Northern Territory, Palmerston North, Queensland, Queenstown, Rotorua, South Australia, Tasmania, Tauranga, Victoria, Wellington, Western Australia

Contact

- Gus Martins 0418328259

- Website Visit

- Email gus@huesker.com.au

ISupplier

- Company Name HUESKER Australia

- ISupplier Profile Visit

About

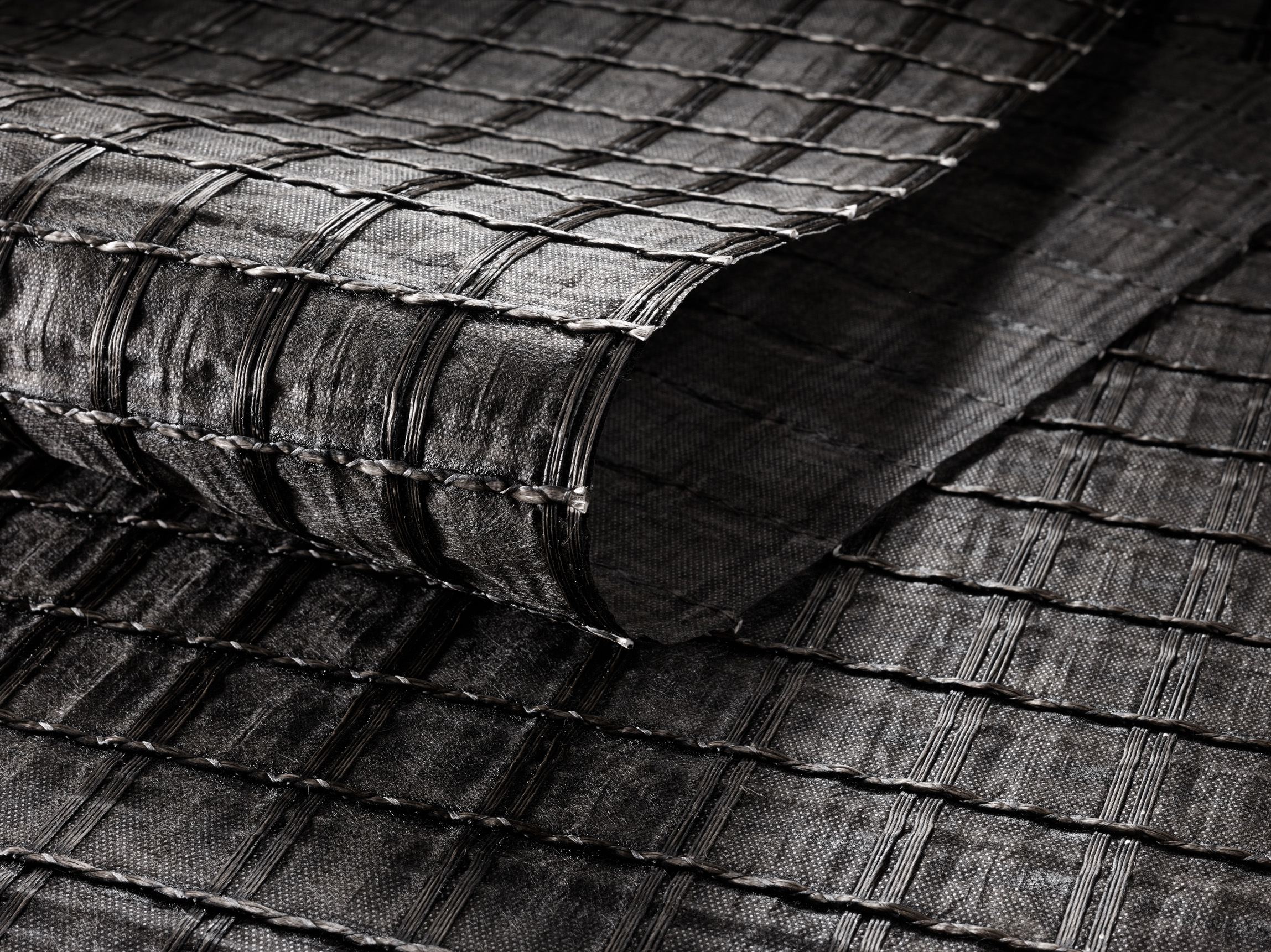

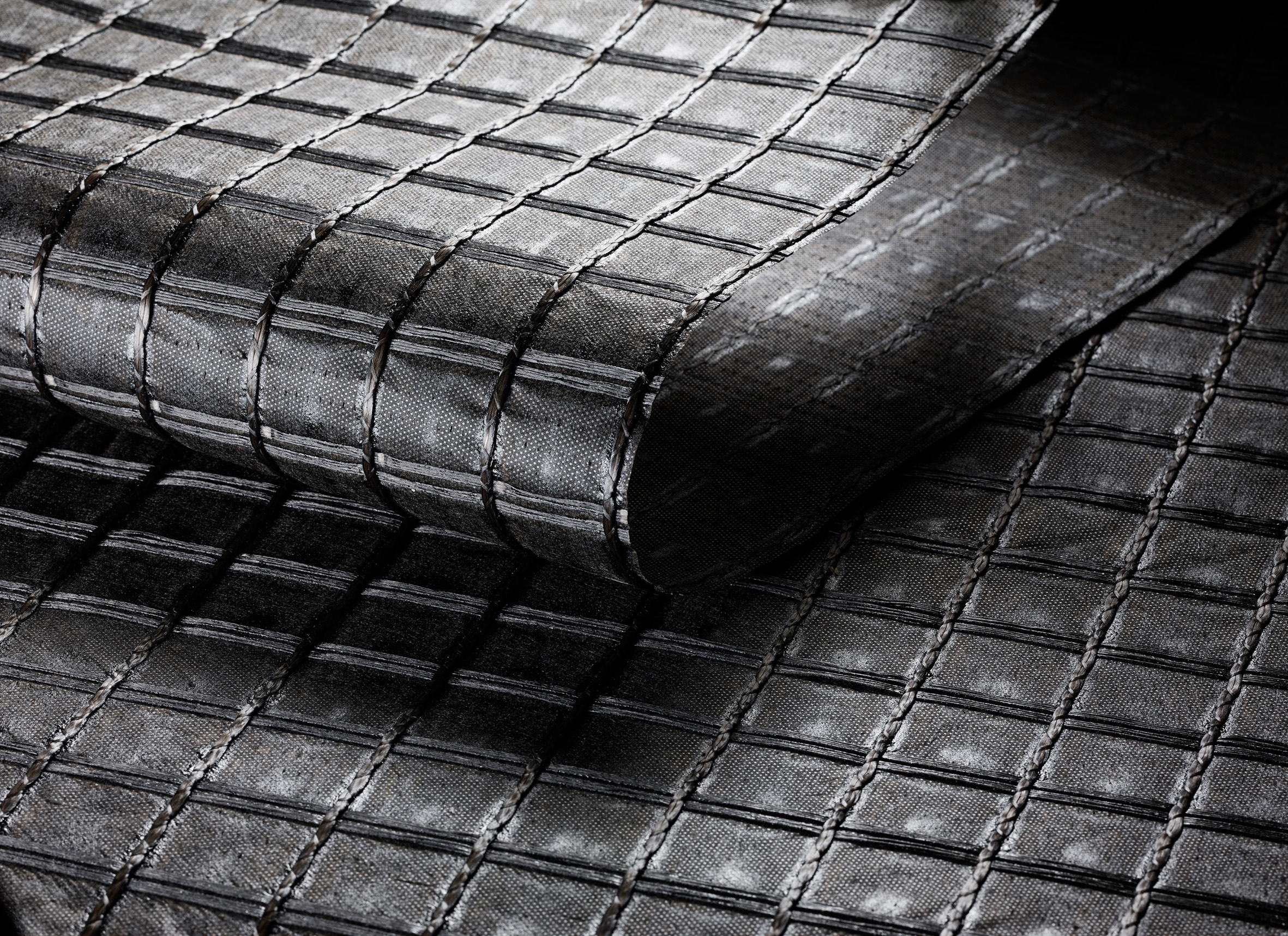

Our Basal T1 and T2 biaxial PP Geogrids and Geocomposites are the standard products for base reinforcement applications manufactured from Polypropylene. Polypropylene is alkali resistant, so can be used even in cement-stabilized soils. These materials are extruded, punched, and drawn Geogrids and Geocomposites. In addition to providing reliable long-term reinforcement for base courses, the carbon black stabilized Polypropylene raw material protects against UV radiation and installation damage.

Sustainability Outcomes

When compared to unreinforced constructions, biaxial Geogrids and Geocomposites reduce the amount of base material required. In addition to increasing bearing capacity, base reinforcement has been proven to be cost-effective, time-efficient, and sustainable.

Applicable Credits

| IS v1.2 | Ene-1 , Inn-1 , Inn-1 , Man-1 , Mat-1 , Wat-1 |

| IS v2.1 | Ene-1 , Inn-1 , Inn-1 , Rso-6 , Wat-1 |

| Inn-1 (ISv1.2) | Innovation | Contributes to Innovation Challenge-8: Sustainable Supplier and iSupply |

| Mat-1 (ISv1.2) | Materials footprint measurement and reduction | Basal T1 and T2 offer several sustainable benefits that reduce the lifecycle environmental impacts of materials. By stabilising base course material, Basal T1 and T2 reduce the amount of material required to achieve soil reinforcement, minimization of base course thickness leads to reduction of large mass transports of soil, thus reducing CO2 footprint. Basal T1 and T2 extends the service life of the structure in comparison to other conventional soil stabilization method, which requires less maintenance and replacement over time. |

| Ene-1 (lSv 1.2) | Basal T1 and T2 can used as an alternative solution for soil excavation and replacement. This would reduce the amount of equipment required to excavate existing soil, transportation of new soil and disposal of excavated soil. Geosynthetic construction with local soil would reduce carbon footprint emissions, energy consumption as well as environmental pollution. | |

| Inn-1 (ISv2.1) | Contributes to Innovation Challenge-4: Sustainable Supplier and iSupply | |

| Wat-1 (ISv1.2) | For base course reinforcement application, fill material is compacted with water to ensure sufficient workability and optimum water is reached to ensure air voids is constant. The use of Basal T1 and T2 can reduce the water demand by reducing the base course thickness, which minimizes the amount of water needed for compaction during construction. As a results, conserving natural resources and it promotes eco-sustainability practices. | |

| Rso-6 (ISv2.1) | Basal T1 and T2 offer several sustainable benefits that reduce the lifecycle environmental impacts of materials. By stabilising base course material, Basal T1 and T2 reduce the amount of material required to achieve soil reinforcement, minimization of base course thickness leads to reduction of large mass transports of soil, thus reducing CO2 footprint. Basal T1 and T2 extends the service life of the structure in comparison to other conventional soil stabilization method, which requires less maintenance and replacement over time. | |

| Wat-1 (ISv2.1) | For base course reinforcement application, fill material is compacted with water to ensure sufficient workability and optimum water is reached to ensure air voids is constant. The use of Basal T1 and T2 can reduce the water demand by reducing the base course thickness, which minimizes the amount of water needed for compaction during construction. As a results, conserving natural resources and it promotes eco-sustainability practices. | |

| Ene-1 (lSv2.1) | Basal T1 and T2 can used as an alternative solution for soil excavation and replacement. This would reduce the amount of equipment required to excavate existing soil, transportation of new soil and disposal of excavated soil. Geosynthetic construction with local soil would reduce carbon footprint emissions, energy consumption as well as environmental pollution. |