The Australian and South Australian governments have jointly committed $354.3 million to construct the Regency Road to Pym Street (R2P) Project as part of their overall commitment to build a non-stop North-South Corridor.

The project comprises an at-grade motorway from the existing motorway infrastructure to the north (South Road Superway); an overpass of the motorway over Regency Road; and an at-grade motorway from Regency Road to Pym Street, transitioning to the lowered motorway infrastructure (Torrens Road to River Torrens Project). The concept design includes:

• a 1.8 kilometre section of non-stop roadway, providing three lanes in each direction (at-grade);

• two lanes in each direction on the South Road surface road, providing access to the surrounding community and local businesses;

• an overpass over Regency Road (three lanes in each direction). Two lanes in each direction (at-grade) on the surface roads underneath;

• left in and left out only access at Pym Street;

• full access to and from the non-stop motorway at Regency Road;

• intersection upgrade at Regency Road;

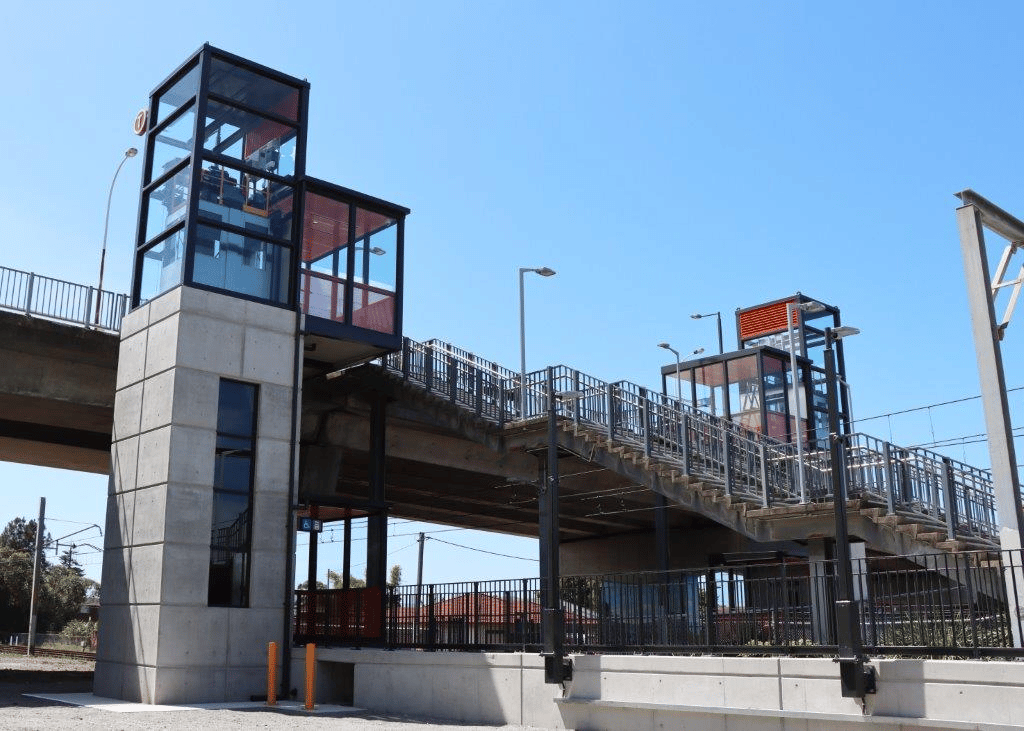

• improved cycling and pedestrian facilities;

• a grade separated pedestrian and cycle overpass over South Road in the vicinity of Pym Street; and

• landscaping and noise barriers.

The project once complete will deliver travel time savings of up to 8 minutes during peak periods (or 4.5 minutes on average) on South Road between Regency Road and Pym Street.

Key Achievements:

Key achievements for the Regency to Pym Street project include:

- Achieved the first V2.0 ISCA Design Rating in Australia, and exceeded contractual requirements for a bronze rating through the achievement of a gold rating.

- Various resource management targets set, and on track to be achieved in the As Built phase, including a 20% reduction in embodied Greenhouse Gas Emissions for Regency Bridge from the base case to final design; use of 90% recycled material for a temporary car park to be spray sealed; reuse of ITS, VMS, gantries and light poles on site where it complies with contractual specifications; divert >90% of waste fill, office waste, organic waste, concrete and low level contaminated waste form landfill; reuse site offices and water collection tanks from a previous project instead of purchasing new

- Green Infrastructure Plan – A green infrastructure plan was developed in consultation with Office for Design and Architecture South Australia and City of Port Adelaide Enfield, which identified targets for water sensitive urban design and a 20% increase in tree canopy cover for public realm area.

- Climate and Natural Hazard Risk Assessment – Three of the six high rated climate risks identified were related to increased temperatures and drought leading to the death of landscaping. Mitigation included use of drought tolerant species and future proofing to allow additional watering.

- A robust system was developed for assessing material sustainability risks and opportunities in the supply chain. This process assisted in the drive of specific sustainable outcomes, such as the use of materials with Environmental Product Declarations (EPDs) – Rso-7 Level 3 was exceeded, increased awareness for the use of Supplementary Cementitious Material (SCMs) in concrete mixes with many mixes exceeding the BAU (20% SCMs) through achieving 30% SCMs; and the requirement to comply with site specific workforce participation targets including local participation.

- Specific workforce participation targets have been set, and are on track to be achieved in the As-built phase, for women in construction workforce (1%), women in construction management (25%), trainees and apprentices (7%), and Aboriginal people (4%).

- Local industry participation of > 95% has been set and is on track for the As Built phase.

- Leaving behind a positive social and environmental legacy through the planting of butterfly gardens in the project boundary, and at local schools in the vicinity of the project. This initiative assisted in providing a suitable habitat for butterflies in urban areas, assisting counteracting the negative impact that urbanisation has on declining biodiversity. A fauna specialist was engaged to drive awareness on biodiversity (and butterflies) at local schools through a STEM (Science, Technology, Engineering and Mathematics) program. The STEM program focussed on creating awareness on what the children can do to promote biodiversity in their local areas.

- Developed and implemented a Multi-Criteria Analysis tool to ensure that sustainable outcomes (social, economic and environmental aspects) are considered in significant project decision making processes.

Rating Highlights:

A 9% reduction in energy use and 5% reduction in embodied greenhouse gas emissions across construction and operation

Energy and Carbon Reduction: a reduction of 9% was established for energy use (which equates to a 5% reduction in greenhouse gas emissions) for the final design (total emissions of 28,633 t CO2-e), compared to the base case (total emissions of 31,471 t CO2-e), the equivalent of taking 1,274 vehicles off the road for 12 months. Initiatives included lower wattage road lighting, method for upgrading motorway pavements requiring less construction fuel and the use of GreenPower at Polonia Site Office.

Material Life Cycle Impact Reduction: a reduction of 5% of embodied greenhouse gas emissions associated with material use was established for the final design (total emissions of 26, 309 t CO2-e), compared to the base case (total emissions of 27,663 t CO2-e), the equivalent of taking 608 vehicles off the road for 12 months. Initiatives included design optimisation reducing materials use (retaining and rehabilitating existing pavement) and materials substitution (use of recycled asphalt pavement, reduced Portland cement concrete, recycled aggregates in kerbing).

Circular economy outcomes in asphalt

To ensure that the sustainability benefits (circular economy and potential greenhouse gas reductions) of asphalt mix containing recycled soft plastics (a Downer product called Reconophalt) were better understood an Environmental Product Declaration (EPD) was developed. The R2P Alliance and the Department worked with Downer and Green Industries South Australia to identify and obtain suitable funding under the Circular Economy Market Development program to assist with the development of the EPD. Both the EPD, and it’s inclusion in the ISCA materials calculator, will allow Reconophalt to be compared to a range of existing generic (and in time, specific) asphalt types already present in the Materials Calculator.

The above referred Reconophalt product was also used in a trial on the R2P Project. Reconophalt, an asphalt product that uses soft plastics as a partial binder replacement in asphalt, was placed on the south bound arterial road section of the project. This was the first use of the product on a Department of Infrastructure and Transport managed road and has led to changes in the Department’s contract requirements on subsequent major projects. The site office car park also utilised soft plastics as part of a 100% recycled asphalt mix. The circular economy outcomes included the use of more than 100 000 plastic bags, 2 500 waste toner cartridges and 324 kg of canola oil for the site office car park alone.

Resource Efficiency Action Plan

As part of Resource Management, a Resource Efficiently Action Plan (REAP) was developed. This plan was noted by the verifiers as ‘an excellent outcome for the project’.

The REAP includes specific headings to ensure that specific information is considered when setting up a project resource management plan. This includes but is not limited to:

- The consideration of all project inputs and outputs

- The initiative selected

- The evaluation of the selected initiative against the waste management hierarchy to ensure that the most suitable option is selected

- Justification for why the selected waste management hierarchy option is the most suitable

- Alternative considerations (e.g. risks, legal requirements, opportunities)

- The project lifecycle applicable (e.g. design or construction)

- SMART targets

- Potential partnerships

- Responsible individuals and due dates

The key positive outcome from the REAP is the thorough consideration of all project inputs and outputs, which assist to optimise the resource management outcomes. The targets set for the project include a 20% reduction in embodied Greenhouse Gas Emissions for Regency Bridge from the base case to final design; use of 90% recycled material for a temporary car park to be spray sealed; reuse ITS, VMS, gantries and light poles on site where it complies with contractual specifications; divert >90% of waste fill, office waste, organic waste, concrete and low level contaminated waste form landfill; reuse site offices and water collection tanks from a previous project instead of purchasing new.

Acknowledgments:

Australian Firsts

Development of an Environmental Product Declaration for Reconophalt

To ensure that the sustainability benefits (circular economy and potential greenhouse gas reductions) of asphalt mix containing recycled soft plastics (a Downer product called Reconophalt) were better understood an Environmental Product Declaration (EPD) was developed.

The R2P Alliance and the Department worked with Downer and Green Industries South Australia to identify and obtain suitable funding under the Circular Economy Market Development program to assist with the development of the EPD.

Whilst there are already a number of asphalt products listed on the International EPD system, the Reconophalt EPD is the first EPD for asphalt registered in Australia and included on the Australasian EPD national database and the ISCA Materials Calculator.

Both the EPD, and it’s inclusion in the ISCA materials calculator, will allow Reconophalt to be compared to a range of existing generic (and in time, specific) asphalt types already present in the Materials Calculator.

It is anticipated that the entry into the Materials Calculator will stimulate further interest in suppliers seeking EPDs for their asphalt products, particularly those claiming sustainability benefits. This will allow projects to have a greater understanding of sustainability benefits when selecting asphalt types for implementation on infrastructure projects.

State Firsts

Use of soft plastics in asphalt

The project trialled the use of soft plastics as a partial binder replacement in asphalt on the south bound arterial road section of the project. This was the first use of the product on a Department of Infrastructure and Transport managed road and has led to changes in the Department’s contract requirements on subsequent major projects. The site office car park also utilised soft plastics as part of a 100% recycled asphalt mix.

The circular economy outcomes included the use of more than 100 000 plastic bags, 2 500 waste toner cartridges and 324 kg of canola oil for the site office car park alone.

Civil Construction Apprentices

An official drive was launched to support Civil Construction Apprentices. A total of 51 Civil Construction Apprentices were appointed to support the future sustainability of Civil Construction skills in South Australia by February 2021.

The use of Site Podium as an alternative Stakeholder Communication Platform

Site Podium, an Application that anyone can access on their Smart phones, was used as an alternative engagement tool on a social media style platform. This App was used for information sharing to, and obtaining feedback from stakeholders. The result was an increased responsiveness from the local stakeholder, which allowed the project team to conduct regular ‘pulse checks’ on the stakeholder health of the project through the use of quick polls on overall community satisfaction.

I-Supply Challenge (using products or services from the I-Supply directory; and referring new or existing suppliers to successfully list at least one new product or service each on the I-Supply directory)

Various suppliers that was already listed on the I-Supply directory were used on the R2P Project, namely Humes for the supply of pre-cast reinforced concrete pipes; InfraBuid Steel for prefabricated reinforced steel cages; SMEC as the project independent verifiers, including health, safety, quality and environmental verification; and Vital Industries for the supply of dust polymers.

Selected suppliers were also referred, and their services or products successfully listed on the I-Supply directory namely Mott McDonald for environmental and sustainability services; Downer for Reconophalt; and Holcim for concrete.

The use of Aural Eyes as an additional community engagement tool

Aural Eyes was used as an additional community engagement tool for improved explanation of the impact of noise treatments. It provides the stakeholder with an audible real time experience of project noise levels through the actual noise played through earphones.

Testimonials:

“Downer’s Reconophalt was born of our rich history of identifying and understanding the evolving challenges our customers face, and working to develop innovative solutions to support our customer’s continued success. We are proud to have developed Australia’s first asphalt product containing high-recycled content derived from true waste streams that would otherwise be bound for landfill, and we are excited to have customers and stakeholders including the South Australian Department for Infrastructure and Transport, the R2P Alliance, and Green Industries SA, embrace Reconophalt and its circular economy benefits.

With the support of the R2P Alliance, the Regency Road to Pym Street project’s stakeholders, and with grant funding from Green Industries SA, Downer published the world’s first Environmental Product Declaration for sustainable asphalt in accordance with ISO14025 and EN15804, setting a new benchmark for ‘green’ products. Reconophalt gives our customers real data, knowledge, and peace of mind as they play their role in the circular economy and actively pursue reduced carbon emissions.

The circular economy doesn’t exist without customers and consumers who close the recycling loop, embracing products comprised of materials diverted from waste streams. We are grateful to have worked together with team members from the R2P Alliance organisations, namely McConnel Dowell, Mott MacDonald, Arup, and the Department for Infrastructure and Transport, who demonstrated cutting-edge thought leadership and a commitment to significant step changes that improve customer, community, and environmental outcomes.

“As a result, the south-bound arterial road and the new Regency Road Reconophalt pavements, together with the R2P Alliance car park pavement comprised of 100% recycled materials, helped the Regency Road to Pym Street project to achieve a Gold ISCA Rating of 64.9, the first V2.0 design rating to be awarded in Australia. Both personally, and representing Downer, I am incredibly proud to have contributed to this impressive outcome, and we extend our congratulations to all involved.”

Brian Eland, Engineering Manager

Road Services

Downer

“The implementation of the ISCA rating on the R2P project has encouraged high levels of collaboration across design and construction staff, and suppliers and sub-contractors, to deliver environmental, social and economic outcomes for the project. We leveraged our supply chain to reduce Portland cement in our concrete mixes and used recycled glass in our pavements for the first time. We have trialled new products including the use of soft plastics in asphalt and shared data and knowledge to assist future project teams to make informed decisions on materials selections regarding circular economy outcomes and greenhouse gas reductions. We have employed the first Civil Construction apprentices in South Australia and engaged with our local communities through the use of a convenient stakeholder engagement app. We have designed the project’s public realm areas to mitigate urban heat island effect through increased tree canopy coverage and water sensitive urban design to build more resilient neighbourhoods.”

Adrian Jones

R2P Alliance Leadership Team Member