Project Description

The Como Station Upgrade Project (the Project) is part of the third tranche of Transport for NSW’s (TfNSW) Transport Access Program, known as TAP 3 and seeks to improve access to public transport for people with disability or limited mobility, parents and careers with prams, and customers with luggage. Providing accessible transport services for everyone in the community is one of the six priorities from TfNSW’s Future Transport Strategy.

Upgrading train stations will provide fair and equitable access for all customers, as well as improving connections between the station and key destinations in the area. Works at Como Station include:

- Construction of a new lift between the station platforms and underpass including associated lobbies and awnings.

- Removal of the existing ramp from Como Parade to the underpass with the construction of a new lift and access stairs from the street level and carpark to provide access to the existing underpass.

- Implementation of a Solar Photovoltaic (PV) Glass canopy on the platform.

- Removal of the existing ramp on Railway Road and the construction of new DDA compliant ramp from the street to the underpass.

- Formalisation of the kiss and ride area on Railway Road with nosing and handrail upgrades to the existing access stairs.

- Regrading and relocation of three accessible spaces in the Como Parade commuter carpark. .

- New accessible pathways throughout the station precinct including the resurfacing of platforms and platform coping tactile upgrades.

- Upgrading of the existing toilets to accommodate one unisex family accessible toilet and ambulant male and female toilets.

- A station power supply upgrade including the installation of new padmount transformer and LV/HV pole adjustments including all associated containment and cabling works.

- New compliant drainage throughout the station precinct.

- Upgrading of the CCTV, Security, AFILS and PA systems.

Rating Highlights

Highlight 1: Climate Change and GHG emissions

Respond to climate change

A comprehensive Climate Change Risk Assessment (CCRA) was undertaken with relevant stakeholders (inc. TfNSW, GHD, Degnan, etc) using TfNSW’s climate risk assessment tools. Mitigation measures have been identified and implemented for 100% of extreme, high, and medium risks identified within the CCRA.

Energy/GHG Reductions

The project design has modelled a 45.7% lifecycle energy and 49.1% lifecycle greenhouse gas emissions reduction over base case, aligning to the TfNSW Sustainability Plan goals and Transport Future Energy Strategy.

This was achieved through the following initiatives:

- Reduction of plant and equipment usage by substituting activities such as concrete piling in favour of rock anchors, removal of shotcrete for natural finishes, and retention of existing retaining walls.

- Efficient Lighting design using LEDs, timers, and Photoelectric cells.

- Efficient HVAC design using Inverter Air Conditioning technologies.

- Renewable energy substitution through Solar PV Glass.

Renewable Energy

Degnan and TfNSW provided considerable effort to research and implement a novel Solar Photovoltaic (PV) Glass canopy manufactured by Onxy Solar instead of a standard canopy design, which will provide the following benefits:

- The provision of up to 58 kWh of renewable energy per day, which is approximately equal to the station’s daily electricity demand.

- The offset of up to 185 tonnes of CO2 emissions within the first 10 years of operation.

- A 29.4% substitution for renewable energy across the asset’s design life.

- Futureproofing for possible electricity export to the grid and storage batteries.

Highlight 2:Improved environmental outcomes

Improve environmental outcomes

The project design has modelled an 18.5% lifecycle water use reduction over base case, supporting the NSW Government’s commitment to resource efficiency.

Materials Impact Reduction

The project design has modelled a 21% material EnviroPoint reduction over base case, supporting the NSW Government’s commitment to resource efficiency.

This was achieved through the following initiatives:

- Reduction of materials by substituting methodologies such as concrete piling in favour of rock anchors, removal of shotcrete for natural finishes, and retention and strengthening of retaining walls in favour complete demolition.

- High SCM replacement within concrete mixed designs, including up to 55% for certain structural and 49.4% non-structural components.

- Substitution of steel reinforcement in favour of E-mesh recycled plastic reinforcement for non-structural components.

- A minimum of 15% RAP in all asphalt mixes.

Highlight 3: Community connection / Respect of culture and heritage

Connecting with communities / Respect culture and heritage

The project has undertaken several community-based initiatives. The three put forward for the Design submission were:

- Vegetation Enhancement: The project proposed to provide 60 trees, 76 shrubs and over 1000 grasses both onsite and within the local area to enhance the vegetation and improve the amenity of the surrounding community.

- Local Disability Employment and Inclusion: The project provided employment and design consultation for local disability groups through onsite catering, construction of recycled timber formwork for platform garden beds, on-site safety walkthroughs, and design discussion workshops. A design update suggested by the St. George and Sutherland Community College was the use of upsized lift call buttons.

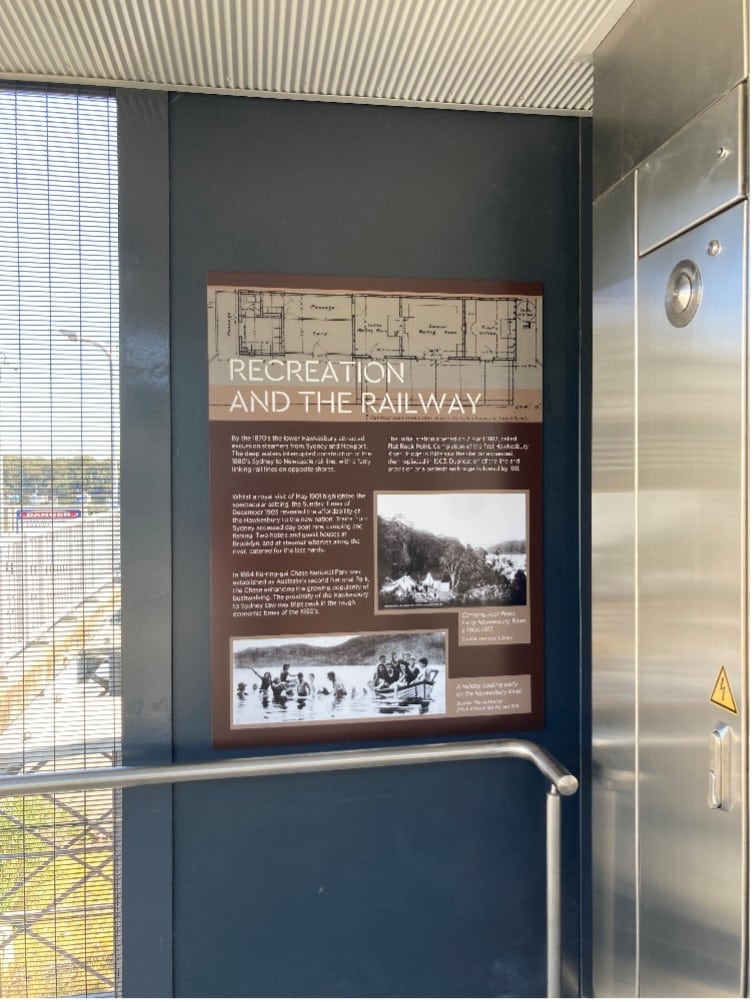

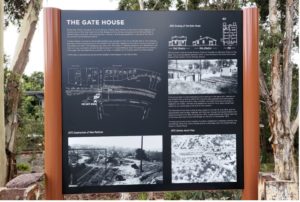

- Non-Aboriginal Heritage Promotion: The project team worked with TfNSW to utilise heritage interpretation to improve the customer and community experience. A heritage photograph of the original Como Station was obtained from the local council library and converted into a custom vertical formwork mould by Reckli® to transpose the image onto the station entrance walkway.

A gate from the original Station Master’s gate house was discovered during construction. The gate was mounted with signage to inform of its original use and its significance in the historical station configuration.

- Aboriginal Involvement in Design: The project has put considerable effort into Aboriginal Community Involvement in urban design. The Kurranulla Aboriginal Corporation was consulted and requested to provide designs and implement 2 artwork murals within the station underpass. The implemented designs reflect the Aboriginal heritage of the lands surrounding the station and significance to the Dharawal People.

These design inputs were facilitated by TfNSW’s Aboriginal Engagement Team and Kurranulla, who were invited to provide a Welcome to Country and Smoking Ceremony at the official station opening ceremony.

- Improved Urban Design: The project team identified the opportunity for an improved visual experience by utilising the natural environmental aspects within the urban design. The lift shaft excavation exposed natural sandstone features which were polished and showcased instead of the original shotcrete design finish. Further sandstone material complimented the excavation walls to improve the amenity of the station entrance and provide the station with a warm and inviting aesthetic for the community.

Highlight 4:Innovative Technology

The Solar Photovoltaic Glass initiative discussed above was verified as an Industry 1st, as below:

- Industry 1st for innovative technology or process – The Australasian Railway Association’s (ASA) Rail Infrastructure Contractors Executive Committee and the Sustainability Committee both endorsed the Solar Photovoltaic Glass initiative as the first application of its kind in the Australian rail market.

- Innovation Challenge IC-4 – The project engaged with 3 organisations listed on the ISupply Directory for products and services to be applied to the project

- Exceeding benchmarks for small project pathways – This project has exceeded the small projects pathway through completion of the full credit requirements. Man – 6, Hea – 1 and Urb – 1